Our Services

Simple & intuitive hardware design to transform your idea.

Telecom

Military / Ruggedized

Consumer

Metak Systems integrates innovative thinking and sound mechanical engineering to make ideas work. Our engineers and designers integrate seamlessly with your product development group.

Industrial & Industrial Design

Security / Scientific

Mechanical Design

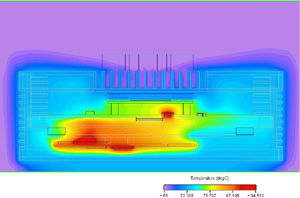

Thermal Analysis

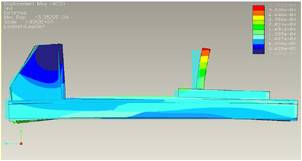

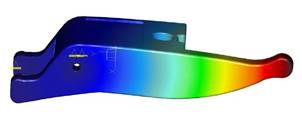

FEA

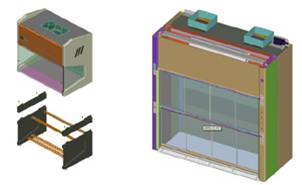

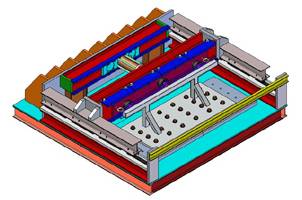

Telecom Products

With over 20 years of experience designing electronics packaging for telecommunication companies, our team offers a breadth of expertise rarely seen in just one company. From multi-card rack mount shelves for Central Office environments to pole-mounted outdoor remote units, Metak has designed products for just about every part of the telecom spectrum. This allows us to assist customers with their system architecture and can aid your company in selecting backplane interconnect, I/O connector, fans, heatsinks, etc.

Working closely with your electrical engineers, we will develop fully detailed PCB common features that capture all the necessary details to ensure that the PCBs interface correctly with their mechanicals.

Being well versed in Bellcore, FCC and UL/CSA, our designs reflect the many years of experience we have in meeting these specifications for telecom customers. Failing to be compliant during certification testing can cause costly redesigns, and lead customers to reject placing your product in their controlled environments. At Metak, experience guides our designs to successful certification testing, and our designs sit proudly in some of the most stringently controlled Central Offices in the world.

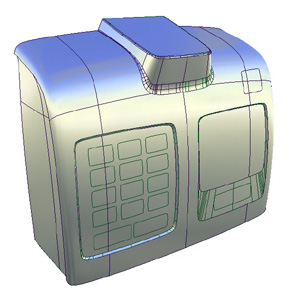

Consumer Products

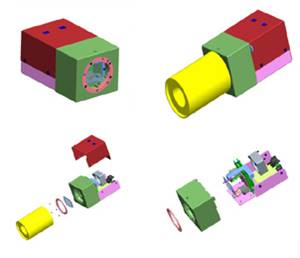

Military / Ruggedized

Industrial Products

Industrial Design

Security / Scientific Products

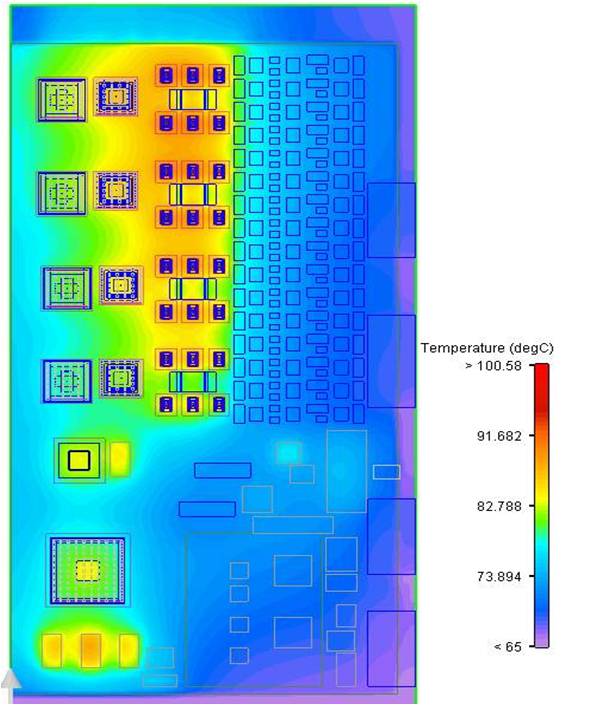

Thermal Analysis

Mechanical Design

FEA

Our FAQs

Frequently Asked Questions

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.